Fabrication

- Home

- /Fabrication

Your Full-Service Trenchless Fabrication Shop. Specializing in Trenchless Units for 17 years.

Our strength and knowledge come from our contracting network proving to be a leader in designing and building trenchless equipment for contractors on a national and international basis. Contractors using LMK equipment are quick, non-disruptive and unique.

LMK Fabrication is capable of 3-D prototyping and machining on a 3-axis CNC machine as well as MIG, TIG, plasma cutting, and metal rolling. LMK Fabrication also builds custom lining trailers and all support equipment necessary to efficiently and effectively renew manhole and pipe lines. LMK Fabrication specializes in custom fabricating Trenchless Equipment to the specific needs of the installer and takes pride in its team of qualified and innovative individuals including an in house engineering staff and a full-time Research & Development Team. We encourage you to learn more about how LMK Fabrication can assist you and your needs for the highest quality Trenchless Equipment and services available by contacting sales@lmkenterprises.com or call 815.433.1275 to schedule your personal tour of the LMK Fabrication facilities.

LMK offers custom fabricated lining trailers and steam curing trucks

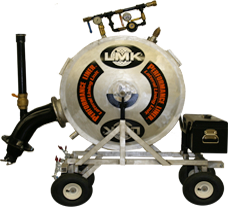

The LMK Inversion Tank is the last word in inversion tanks and lateral lining equipment. This launcher allows the rehabilitation of a lateral pipe through a cleanout directed either upstream, downstream, or even through an inside cleanout. The tank includes 3 safety valves, windows, and a pressurized camera port that allows the installer to visually verify that the liner has been fully deployed before cure without ever dropping air pressure.

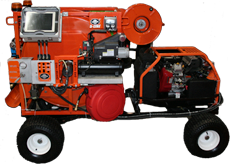

The LMK Cleanout Rig is a mark of how convenient and efficient we make CIPP lining for you. This vehicle is fully equipped with everything the installer needs to have ready and on hand at the cleanout, ensuring the preparedness of the crew and resulting in the success of the overall end product. Features of the cleanout rig include a push camera and rod, a shop vac, a generator and quick connect air hose, any necessary tools, and a safety eye wash station. For more information about how LMK custom manufactures vehicles please contact our sales department.